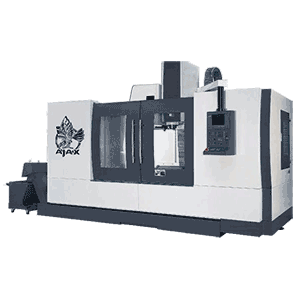

High Speed Vertical Machining Centres.

Ajax Vertical Machining Centres – Built for Precision and Performance

Our range of Ajax vertical machining centres is engineered to the highest quality standards, using only premium components to ensure exceptional performance and durability. The “V” stands for velocity – because speed and efficiency are essential in today’s demanding production environments.

These machines deliver outstanding precision, reliability, and speed – everything modern manufacturing requires.

Get in touch with one of our experienced engineers or email us today to discuss how we can meet your machining needs.

Ajax staff can advise on the best option for your workshop solutions. CE & CA Marked.

For more information about control systems, please click here.

High Precision Calibrated.

Precision You Can Trust

All our machines are calibrated to the highest standards using a Renishaw laser system, ensuring ultra-high precision across every axis. To further guarantee accuracy, we validate alignment and performance using the Renishaw Ballbar system, which measures circular interpolation accuracy in two axes during live motion. This dual-stage verification process ensures that every machine we deliver meets the strictest precision requirements.

Specifications.

Media.

Unmatched Accuracy with Renishaw XL-80 Technology

At Ajax, accuracy is paramount. We are one of the very few companies in the UK equipped with the Renishaw XL-80 laser measurement system—a cutting-edge tool capable of detecting movement at the nano-scale (one-thousandth of a micron, which is itself one-thousandth of a millimetre).

This ultra-precise data allows us to calibrate our machines to extremely tight tolerances. Typical results across the entire working envelope are within ±0.002 mm, far surpassing what most competitors can achieve—or even measure.

We can perform this calibration on-site and offer annual recalibration services to ensure your machines continue to operate at peak accuracy year after year.

High-Speed Machining with Consistent Quality

Ajax machining centres are designed to deliver high-speed processing with reliable repeatability and superior surface finish. Every model in the range is built on solid cast iron columns and bases, effectively eliminating vibration to enhance stability and cutting accuracy.

Rigid tapping comes as standard, ensuring efficient and precise thread cutting.

Our machines also feature a random-access tool changer equipped with an air blast system that cleans the spindle before each tool change, ensuring optimal tool engagement. Additionally, air blast during machining helps keep the workpiece clear of chips, improving both visibility and finish quality.

Advanced Control Options – Precision Meets Simplicity

Ajax brings together the perfect balance of quality, reliability, and value by offering a range of industry-leading CNC control systems to suit your machining needs:

- Fanuc 0i-MF Plus

Trusted worldwide for reliability, this control comes standard with Ajax machines. The Manual Guide i option provides easy-to-use conversational programming for simplified operation and faster setup. - Heidenhain Controls

Choose from the TNC 320 (entry-level analogue), TNC 620, or the TNC 640, which has replaced the TNC 530 as Heidenhain’s flagship control. All models use the same intuitive programming language, ensuring smooth upgrades and operator familiarity. - Siemens 828D & 840D

High-performance controls with the option of ShopMill conversational programming, ideal for efficient and user-friendly operation in complex machining environments. - Fagor 8058 Elite & 8060

These powerful conversational controls offer flexibility, ease of use, and precise machining performance across a wide range of applications.

Ajax, milling around the world.